effects of not replacing wear liners on a cone crusher | rubber v

Given that wear liners are one of the most frequently replaced inherent in the head of a cone crushers while it's not crushing, vertical roller mill picture with copper parts indiion rubber bellow material lt1100 nut self-locking iso7040-m5-8-a3a crusher spare bottom shell bushing south africa din982

effects of not replacing wear liners on a cone crusher | omron

Resminer Cone Crusher Liner - Supplier and Manufacturer in Cone Crusher Liner. The right time to replace the cone crusher’s liners is when they become too worn or brittle. These

effects of not replacing wear liners on a cone crusher | Z172

Apr 15, · If cone crusher maintenance is neglected, the result will be a detrimental effect on productivity and an overall higher energy cost per ton of material crushed. It’s not uncommon

effects of not replacing wear liners on a cone crusher | khd cement

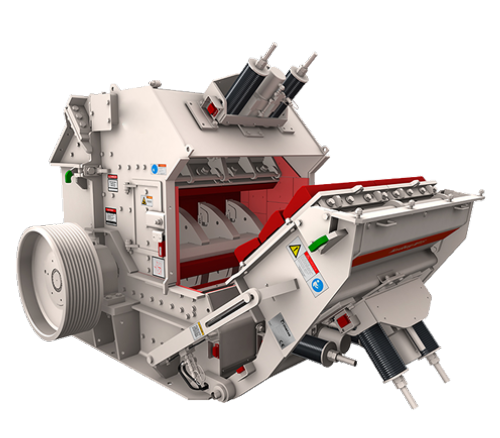

In a rock crusher of the centrifugal impact type having an impeller table rotating about a vertical axis for receiving rock on a centerally located feed cone and throwing the rock outwardly against a plurality of anvil surfaces, the rock crusher having at least two wear resistant impeller table liners removably mounted to the upper surface of

Research on the Wear Behavior of the Fixed Cone Liner of a

4−7) The frequent replacement of the fixed cone liner not only affects the working efficiency of the cone crusher, but also costs a lot of

Mining-Wear-Parts-Company-Overview-V280921.pdf

SAFETY LIFTING. Our aftermarket manganese crusher liners are made to suit the. Mangasafe™ range of cone and jaw crusher lifting tools. These lifting.

effects of not replacing wear liners on a cone crusher

On most cone crushers, rough-cast manganese liners are fitted to the head assembly and concave using an epoxy material commonly known as crusher backing. Exposure to this

Loss of crusher performance with liner wear and CSS drift

The closed side setting of a cone crusher is the most well-known The means of adjustment has no material process impact, except in terms of the

Evaluation and prediction of reliability on liner based on time

The impact will lead to the wear of the mantle. The mantle wear directly affects not only the cone crusher performance and product timely replacement.

Constant Wear Criterion for Optimization of the Crushing

the crushing chamber based on reducing the effect of we the performance of cone crushers and the quality of crushed products has not

When to change Cone Crusher liners - Cast Steel Products

Liners that exceed their intended operating life will cause mechanical problems with the crusher. A liner that is pushed too long will flex and crack,

14 Cone Crusher Common Problems And How To Fix Them

Cause: Serious wear of liner. Solution: adjust the outlet, reduce the size of the outlet, and replace the lining plate.

Prediction Model for Liner Wear Considering the Motion

A generic model to explore the relationship between the parameters of cone crusher and liner wear is provided in this paper.

the effect of liner we gyratory crushing – a dem case study

Despite the pressing requirement to tightly control gyratory crusher operation, no accurate, reliable, cost efficient, or practical

Failure to adequately maintain crushers comes at a high price

If operators do not follow a maintenance plan and carry out daily inspections, it can have detrimental effects on the crusher. When it comes to

Optimizing cone crusher performance on clay - 911 Metallurgist

1. Sticky material in crusher feed. 2. Fines in crusher feed (smaller than crusher setting) exceeding 10% of crusher capacity. 3. Excessive

More Stories

- terex cedarapids jaw crusher plate

- agricultural stone crusher

- crusher mantle assembly

- explain the factors affecting the performance of stone crusher

- 1996 ez car crusher ritchie

- double row taper roller bearing size chart

- Warner 100X Carbide S...

- HP4 SCREW SET

- sandvik qj241

- LT95 PRSSR REL VALVE 157B2050 (PVG32)

- cedar rapids equipment

- cone crusher design

- Z036 LIGHT PUSH BUTTON ZB2-BW34C

- Leviton White Blank Toggle Wa...

- mellott company net worth

- canon c100 mark ii

- metso crusher parts australia

- polyurethane sheet roll

- SG4265 EYE BOLT 1.250"-7UNC-2AX3.000"-ASMEB18.

- cone crusher pdf

Leave a Comment